unl-digifab

Week 2 - Laser Cutter

Tuesday

- Review Rhino 2D Basics

- Topics

- Intro to Laser Cutter (hardware hands-on)

- Cutting

- Design for Laser Cutter

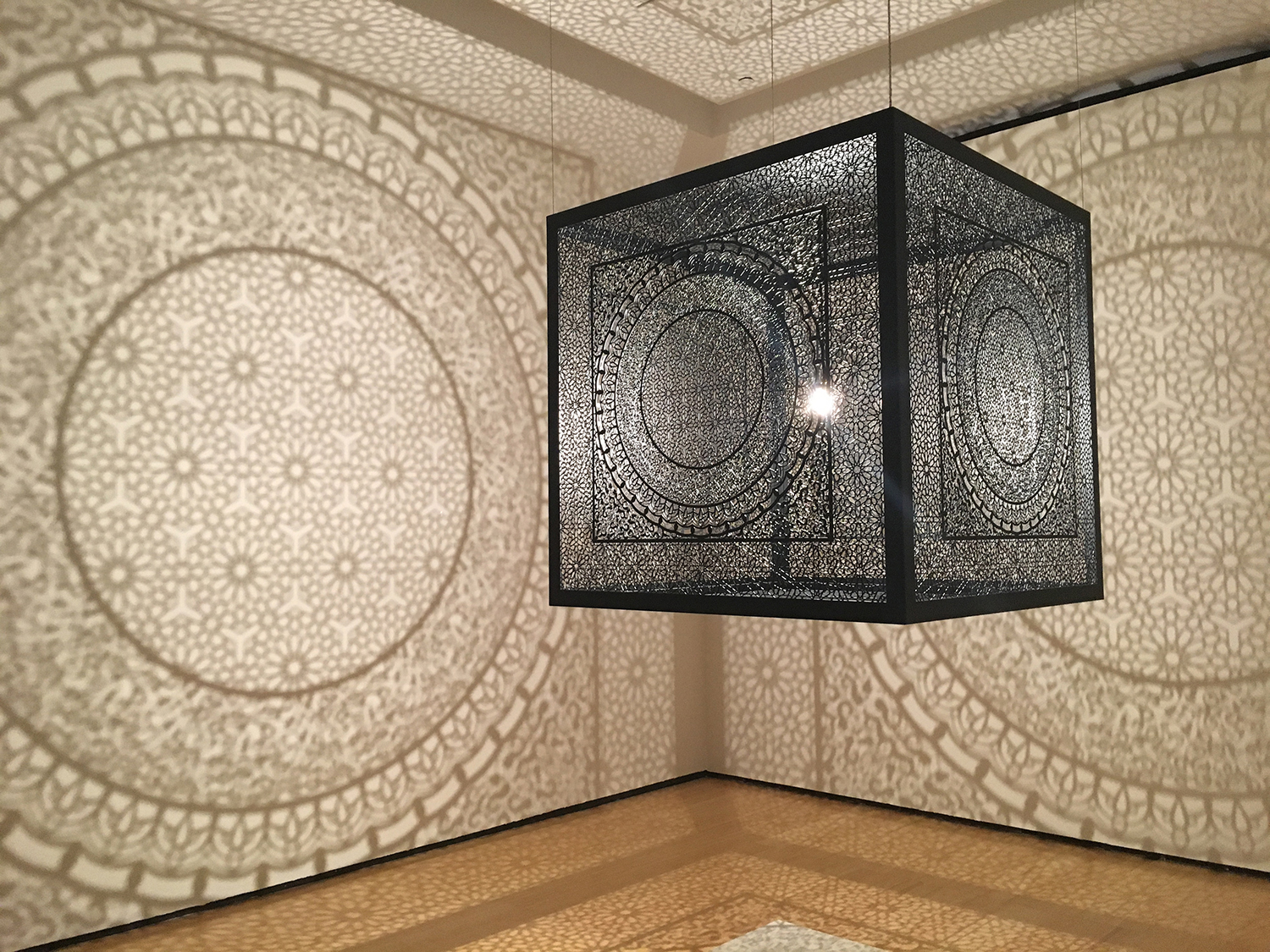

Artist of the Day

Review

Rhino 2D Basics

- Create new file from template. Small objects inches.

- User interface:

- Switch between single and quad (four-up) display.

- Pan, tilt, zoom in display.

- Turning Grid Snap on and off. (To create points that stick to origin, 0.25in, etc.) Try as a text command: Type Snap once to turn it on. Once to turn it off.

- 2D Primitives

- 2D Operations

- Organization

- Layers. Using layers.

- Group

- Ungroup

- Selecting. How to Select things with the mouse.

- Selection Menu

- Transforms

- Direct Manipulation

Example File 2D Basics

Rhino file: basic_drawing

Intro to Laser Cutter

Hands-on with our FSL Muse 3D (Full Spectrum Laser):

1. Laser basics

- Safety (air filtration; fire safety)

- ALWAYS before you cut: turn on the Water Cooler, Exhaust, Air Assist.

- The Muse has two lasers, actually: an infrared CO2 laser (actually cuts our materials), and a visible light Red laser (for knowing where you are going to cut)

- We also have a 3d camera. This is useful to capture an image of workspace (2D) to lay out a cut on our material. In 3D mode we can do some etching/engraving on irregular and three dimensional materials. That is an advanced topic.

2. Material choice

- Good materials for laser cutter:

- thick papers (card stock, manilla folder, index cards, office paper, watercolor paper, bristol board, vellum)

- thin cardboard (poster board, matte board, corrugated cardboard - i.e. cardboard boxes)

- plastic sheets (acrylic, ABS)

- wood (architectural plywood, balsa wood, thin birch plywood, veneers)

- engraving on leather

- textiles

- Bad materials:

- anything vinyl (PVC plastic tube and sheet, vinyl decals)

- polystyrene (i.e. styrofoam, packing peanuts)

- What other materials do you have questions about?

3. Laser Settings

- For any given material, we need to find the right power settings.

- There are three parameters we set: Speed, Power, Current.

- (see the chart at the bottom fo the page for some starting points for different materials)

- We can do formal tests to find the best parameters. See this Materials Test procedure.

- (we can also do this a little more informally)

- Blog post on Laser Settings for Cutting

- Over time, we (as a Center) will come up with our own materials settings that work well with our laser cutter.

- So, log your cuts: (date, time, material, thickness, power settings)

- (we need this to build our library of materials and settings)

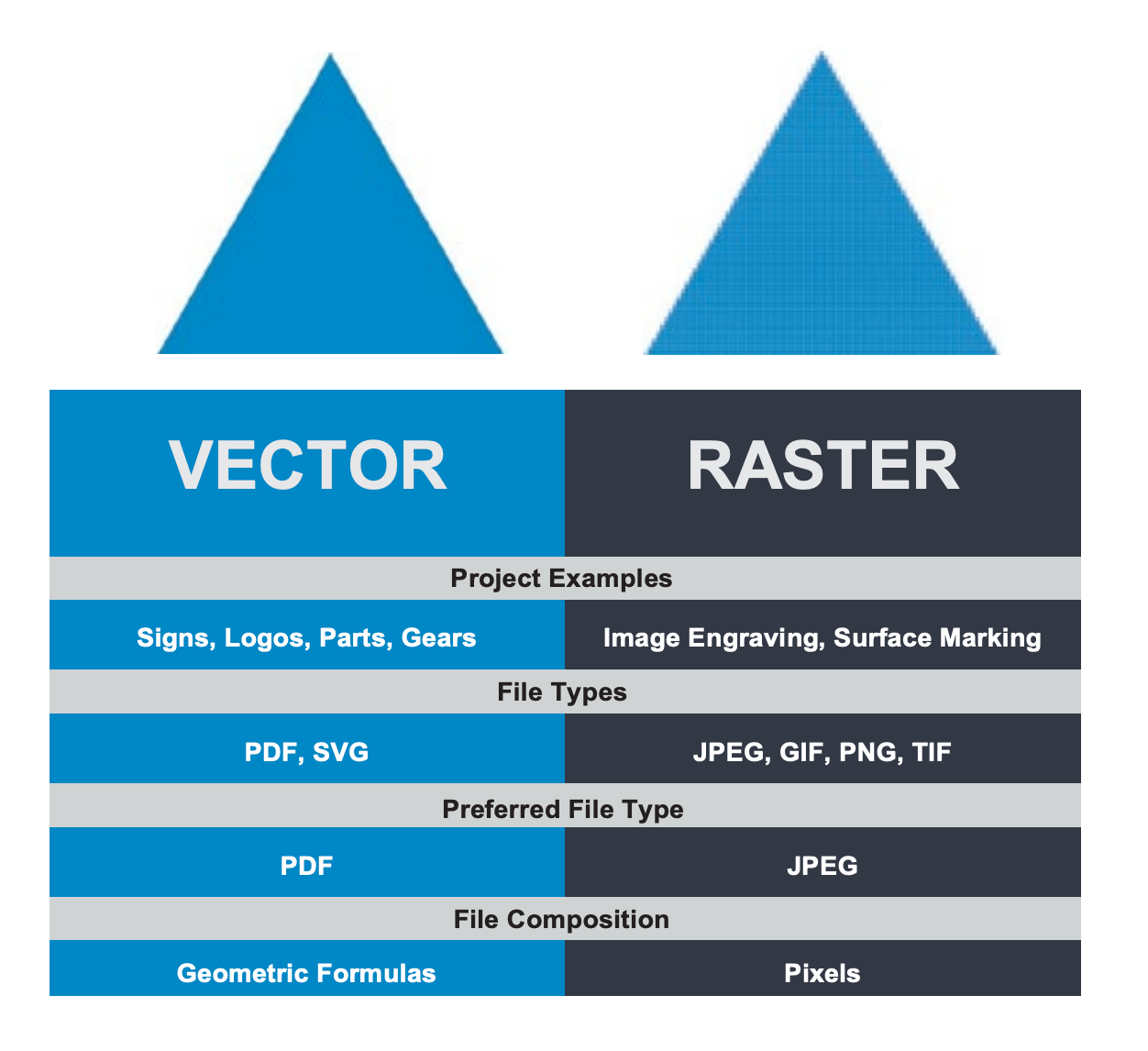

4. Cut Types

- Engraving vs Cutting:

- Engraving: marking patterns into the surface of a material (faster, lower power, can engrave materials like glass, stone that can’t be cut through)

- Cutting: cutting through the material. (slow, higher power, smokes/catches fire)

- The difference is whether you are cutting through the material, or marking the surface.

- The power of our laser tube (45 Watts) determines what thickness we can cut through. Higher power lasers (65-75W, 100W) can cut through thicker materials. But there are still limits. The fiber laser (Innovation Studio) is a whole different laser type that can cut through 0.25” plate steel, for instance.

- There are three main operations we will do:

- Vector Cutting: cutting shapes out of materials. this is the bulk of what we will do. SVG files.

- Vector Engraving: using vector art to mark the surface. designs, patterns, cross-hatching. SVGs.

- Raster Engraving: rendering a bitmap on the surface of something, row by row like an old school printer. BMPs.

- In the Muse software (RetinaEngrave), “Cutting” and “Engraving” are both called Engraving. We just choose different power settings. See the chart at bottom of the page.

5. Cut demos

- We will use your HW1.

- Let’s double check/fix our HW 1 and then cut some.

Cutting

Full Spectrum Laser has their own engraving software called RetinaEngrave. We will use it from the workstation on the laser table.

- Create Design

- Open RetinaEngrave on the workstation. (Desktop Shortcut, or Safari ->

fslca88.local) - Import the design (SVG file). We will use HW1.

- Place your material in the laser cutter

- Secure your material (blue tape)

- Capture workspace (camera)

- Change your line colors/layer colors, if you need to.

- Change your scale/placement, if necessary.

- Set the engraving properties - Vector Engraving (note, it is all called “engraving” in Muse)

- Turn on Water Cooler; Exhaust; Air Assist.

- Run job.

Design for Laser Cutter

Simple Laser Cutter Design

- Create new file from template. Small objects inches.

- Drawing in 2d; using layers

- Optional: Extrude your layers to the thickness of your material, to see what this would look like as cut.

- (f.ex. for 1/8” birch plywood you would extrude it to something like 0.125” thick. you can use your calipers to check these measurements)

- Exporting to SVG.

Thursday

- Artist of the Day

- Tutorial

Artist of the Day

Ben Butler

- https://mymodernmet.com/ben-butler-organic-sculptures/

- https://www.benbutlerart.com/

Tab and Slot Construction

- How can we build 3d structure with 2d materials?

- Tab and slot construction? (also called finger joints)

- You need to design 2d parts that have holes (slots), and other parts that have tabs, so that when cut from flat materials you can assemble them into 3d forms.

- Optional: Extrude your designs to the thickness of the material, to make solides. Assemble these solides in Rhino to mock up your 3d form.

- Reference (Video Tutorials):

- Finger joint laser cut box: https://www.youtube.com/watch?v=FBSQGHBpBWg

- Finger joint tutorial in Rhino with boolean operations: https://www.youtube.com/watch?v=AYxUUSWIRW4

Measuring Thickness

- Using calipers. See Sparkfun: How To Use Calipers (youtube link)

- Cutting tests.

Matching Parts

Example Two Slots

Rhino file: two_slots.3dm

Living Hinge

- Living hinge construction

- Kerf Bending Experiments: https://www.martin-breuer.com/kerf-bending-patterns

- Lattice Hinge Design Workshop: https://futurearchi.org/t/lattice-hinge-design-workshop-starting-from-an-open-source-grasshopper-design/576

- With grasshopper: https://github.com/StDrunks/Living-Loop

Homework

- Ideas for project 1

References

- For your reference: Rhino Learn (tutorials)

- Sketchup to Rhino Cheatsheet

Laser Cutter Reference

- RetinaEngrave Software:

- FSL Muse References:

- Muse 3D Manual

- FSL Muse specifications, safety documentation.

Power Settings

- Suggested starting power settings for FSL Muse (do tests and adjust these for your project):

Leftovers

- Slicing / panelling tools (breaking 3d structure down into 2d components that can be assembled)

- Parametric design for kerfs and 3d structures (grasshopper)